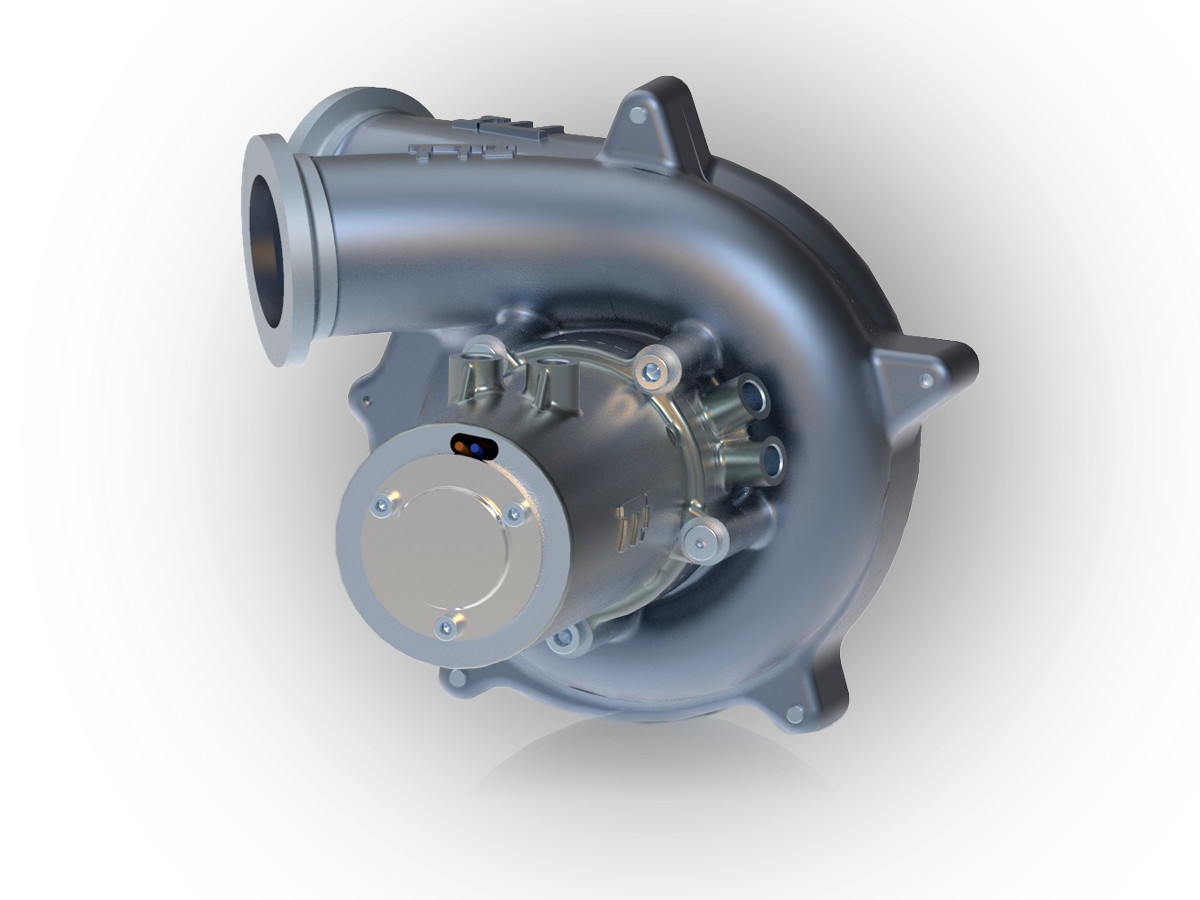

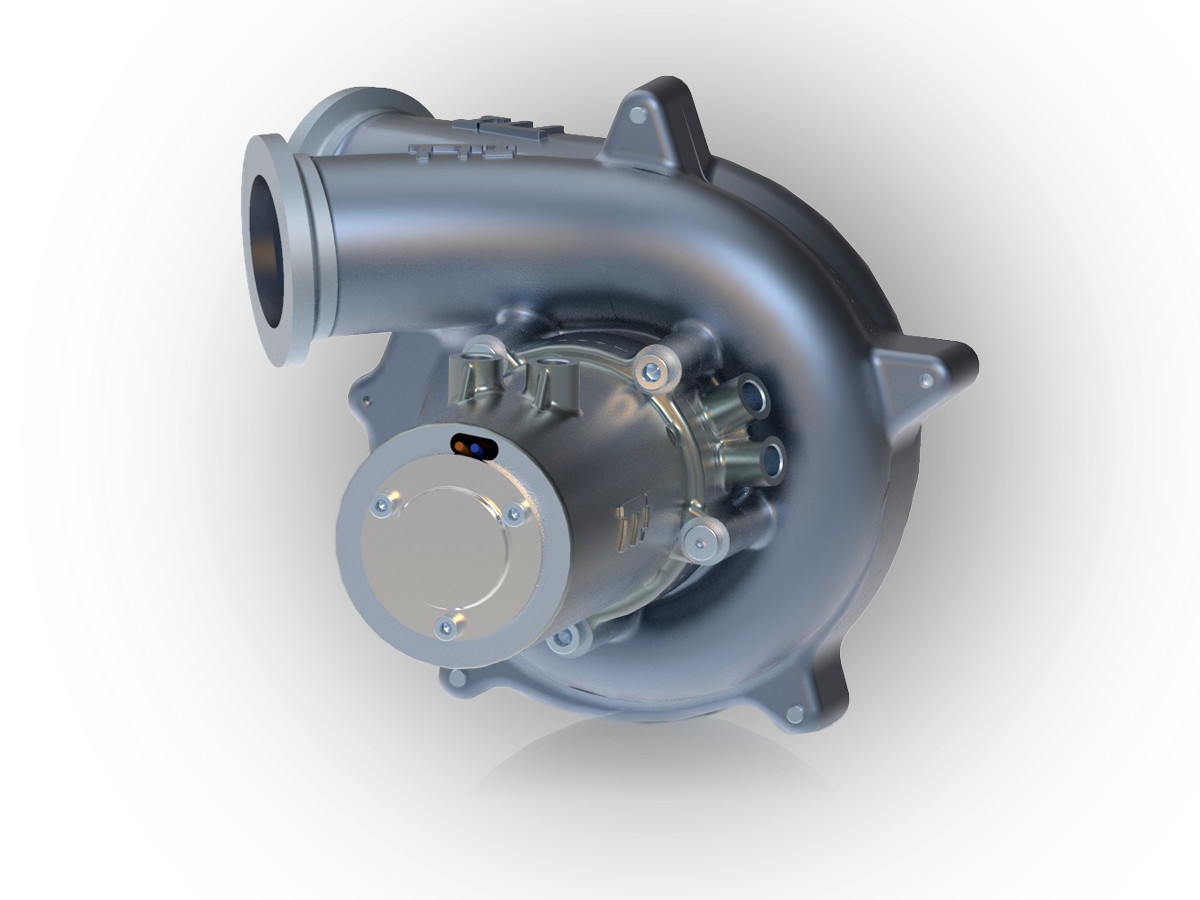

Turbocharger

- High specific power (downsizing)

- Low fuel consumption and

- Low emissions

By customers order TTI does development and optimization on turbocharging systems.

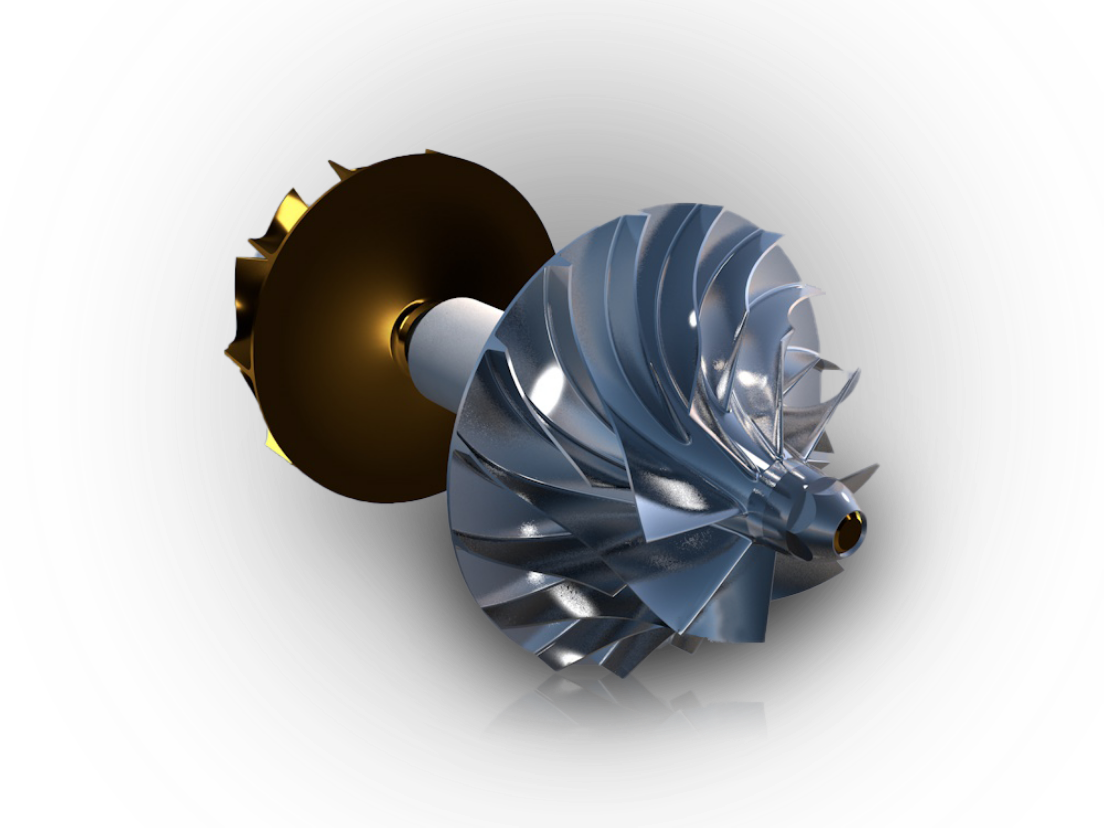

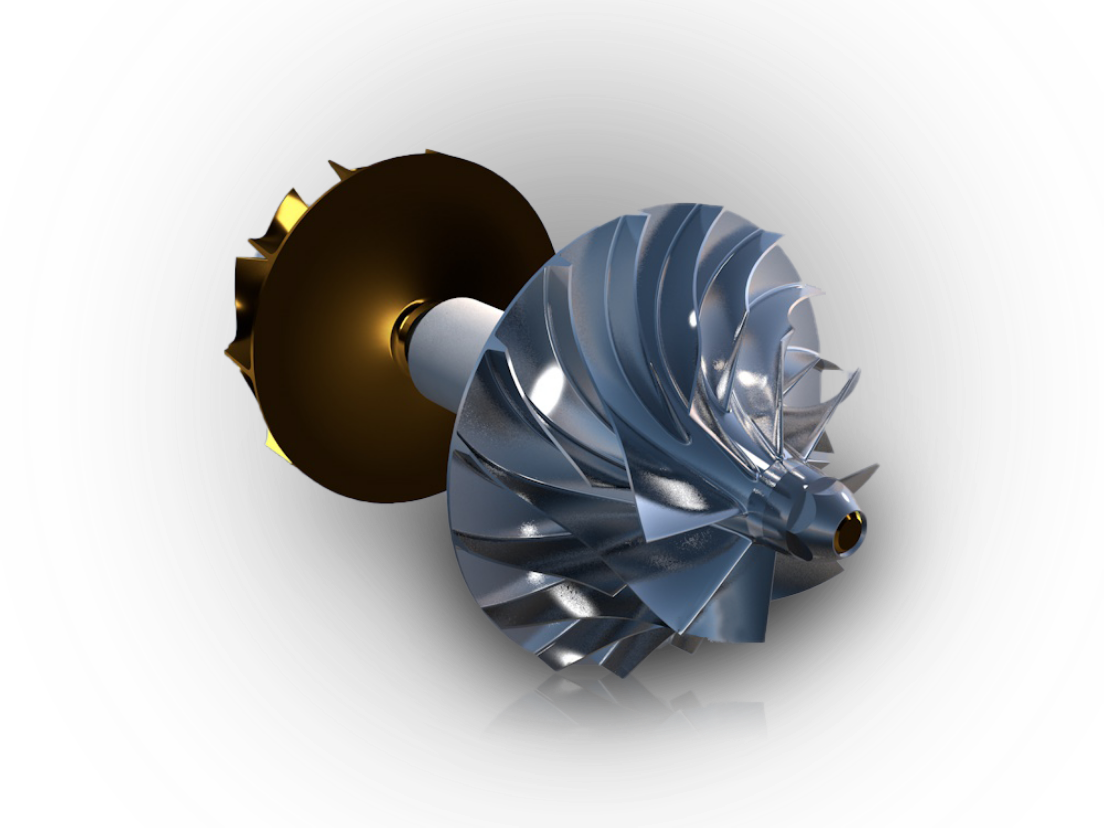

Electric driven turbo compressors

- high compression efficiency

- small package

- low weight

- advantegous acoustic behaviors (NVH)

- oil-free bearing system

Engineering services & parts

Technical development (design and simulation) and

Procurement of parts (components and assemblies)

a complete package from one source is getting delivered to our customers.

All scope of work (e.g. only services, only parts or both) are individual agreed with customers demands and also may be exceed our special subject “turbomachinery”.

Research & Development

Future.Focused.Innovation.

Turbocharger

Main features of future focused developments are variable control of flowpath geometry and controlled multi-stage systems as well as the use of new material technologies.

Electric driven turbo compressors

- E-turbo (turbocharger w/ coupled generator/e-machine)

- e-booster

- air supply unit for Fuel cell application

- multi-stage high pressure compressor

Here the core capabilities of TTI are:

- Development of turbo components

- Development of bearing system

- Integration of electric components

- Cooling system / Heat management

- Assembly of prototypes and small batches

- Testing

Engineering services & parts

TTI Turbo Technik Innovation GmbH

Leverkuser Strasse 65

42897 Remscheid / Germany

Telefon: +49 (0)2191-59146-0

kontakt(at)tti-automotive.de

Development

Engineering Services & Parts